Wiki project: Compressed Air Energy Storage

Wiki project: Compressed Air Energy Storage

Jiem Nguyen

In today’s current society, energy consumption has been a growing issue on a global scale. In most cases, problems have stemmed from the inefficiencies of creating and storing energy. While the development of these issues are currently under study, there are techniques used today that currently help with this problem. One main issue with the power crisis is that if energy isn’t used immediately, it is wasted. This in turn adds more problems with distributing power to people since the demand shifts on an hourly basis. So one technique is to store energy in the plant during the off-peak power generation hours.

One simple way of ‘storing’ energy is with a battery. They are small, lightweight, and can be manufactured easily. One question that arises is why not build a big battery that can charge and recharge on a global scale? In short, it would be a very inefficient due to how fast stored power could be extracted, as well as the resources it would cost to build. A battery is geared towards smaller devices, such as mobile phones. They shouldn’t be used on a massive city-like scale. When it comes to city sized power storage, there is one process that helps counter the problem, Compressed Air Energy Storage (CAES).

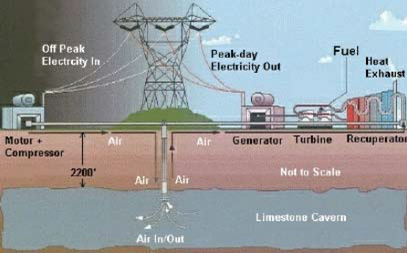

A CAES plant works by storing air in either an underground cavern or vessel. It gathers the power from off peak electricity to compress the air into a storage area. Since compressed air creates heat, the turbines can use that heat to create energy. When the demand increases in the evening, the plant can take the stored air and heat it up. The now (thermally) expanded air is fed through a conventional turbine-generator to produce electricity. See figure 1 for a visual representation.

Figure 1: CAES Process

One of the main drawbacks of a CAES system is how the plant extracts the heat from the air. Thermal expansion requires heat, and if no extra heat is added, the expanded air will be much cooler. This cooled air reduces the amount of power extracted from the heat. In other words, a CAES uses heat to create more heat, which is then extracted for power. In theory, it is possible to have a system that doesn’t need any external resources, but in practice the system can quickly lose its efficiency. There are different processes where the system reuse the heat, Adiabatic and Diabatic.

A Diabatic process tries to mimic an Isothermal process to compress air (where there is 100% efficiency) but an Isothermal is more realistic for a small scale plant. The extra heat is lost from intercoolers (which are needed in this process) when the air is compressed. The air must be reheated when it is extracted from storage, and uses an external sources such as a gas burner. This process roughly has a 50% efficiency rate. In other words, you only extract 50% of the energy stored from heat. An Adiabatic tries to store the dissipated heat used in compressed in liquid (such as oils) or material (such as concrete). It reuses the heat in the expansion process, therefore having roughly a 70% efficiency rate. Table 1 shows three different plants and how the CAES process is used in today’s market.

|

Normal capacity (MWh) |

output power (MW) |

Energy density (Wh/L) |

power density (W/L) |

normal charge discharge duration (hours) |

response time (min) |

lifetimes in cycles |

roundtrip efficiency |

capital cost per capacity ($/kWh) |

|

|

Underground plant. |

1440-3600 |

180 |

Low1 |

Low1 |

8 – 26 |

9 – 12 |

(>13,000) |

54% |

120-603 |

|

Underground plant with a combustion turbine |

1080-2700 |

135 |

Low1 |

Low1 |

8 – 26 |

9 – 12 |

(>13,000) |

54% |

125-603 |

|

Aboveground plant |

250 |

50 |

Low1 |

Low1 |

5 |

9 – 12 |

(>10,000) |

54%-70%2 |

390-430 |

Table 1: Statistical uses of a CAES Plant

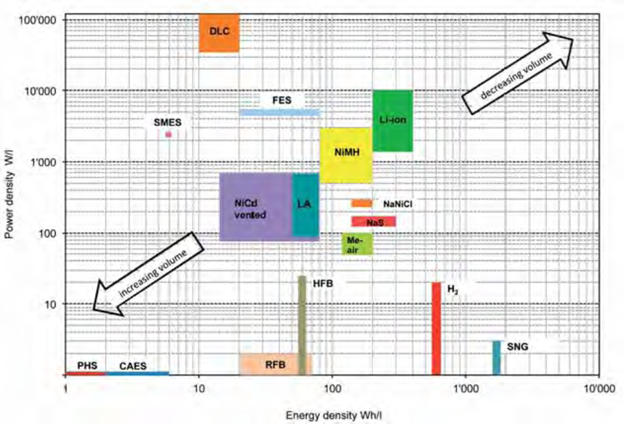

1: See Graph 1

2: Unsure of what type of process is used (Adiabatic or Diabatic)

3: Not levelized. If leveized, process should be only 15-20 cents $/KWh

When Comparing CAES to similar system, such as a Hydro-pump plant, it is understandable why CAES aren’t used more. A Hydro plant has a 76%–85% efficiency rate compared to a CAES system, and holds over 99% usage of electrical storage. However the strength of the power plant is determined by a geographical location which limits its size. CAES power plants are also constrained by a geographical location, but instead of water, it needs a solid underground cave that doesn’t allow air to lead. This can be mimicked on land, but it requires a great sum of money to build. CAES is also in its infancy phase, and research has shown that there are ways that allow CAES plants to run at 70% efficiency, which is still growing.

The graph below shows the Power density vs. Energy density levels of a few energy storage devices. It show that Hydro-Pump and CAES units have low densities levels, but that is completely fine since these two units are used for storing energy instead of using or delivering it. Perhaps in the future, when CAES is more fully developed, it will be used more often as a large scale energy storage device.

Graph 1: Comparison of power density and energy density (in relation to volume) of

EES technologies 4

Sources:

- http://www.sfu.ca/~mbahrami/ENSC%20461/Project/Some%20papers%20for%20HRS/Overview%20of%20current%20and%20future%20energy%20storage%20technologies%20for%20electric%20power%20applications.pdf

- http://en.wikipedia.org/wiki/Compressed_air_energy_storage

- https://blackboard.binghamton.edu/bbcswebdav/pid-2128211-dt-content-rid-9812912_2/courses/EECE512X-01_SPG15/Electricity%20Energy%20Storage%20Technology%20Options.pdf

- Fraunhofer ISE http://www.iec.ch/whitepaper/pdf/iecWP-energystorage-LR-en.pdf Page 32