Energy Storage via Flywheel Technology

Discussion in this article will focus on flywheel energy storage technology based on information from the paper entitled Electricity Energy Storage Technology Options: A White Paper Primer on Applications, Costs, and Benefits by the Electric Power Research Institute (EPRI).

Basic Operation:

For this form of energy storage technology, a rotor, composed of very strong materials, rotates, storing kinetic energy, which is then discharged through a generator. Flywheels obtain their kinetic energy from electrical energy via the grid during periods of low power demand and release this energy as the wheel decelerates in the absence of the grid charging spin. Magnetic bearings allow the wheel to hover and rotate with minimal shaft friction within a sealed vaccum chamber, resulting in very high efficiencies of up to 95%.

Applications:

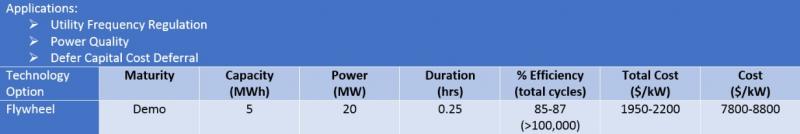

As of 2011, there are around 10 or more field units capable of producing 1 MW to 20 MW of power in the United States, each for various uses in power quality applications. Flywheels are typically not suitable for supplying bulk power to the grid, as they generally store energy for shorter durations than desired for such large scale application. Consequently, much of the energy stored in flywheels are used for power quality and uninterruptable power supply uses. There is research currently focused on the development of flywheels for larger-scale uses. The energy density of flywheels varies by flywheel design and is largerly dependent on the materials and arrangenet of the materials that the flywheel is composed of. Composite flysheels can thus have energy densities ranging anywhere from 100 Wh/kg to up 1000 Wh/kg. Table 1 below gives a general overview of flywheel parameters in relation to frequncy regulation, a role this technology is currently most commonly used for.

Table 1: Energy Storage Options for Frequency Regulation and Renewable Integration

Parameters and Comparison:

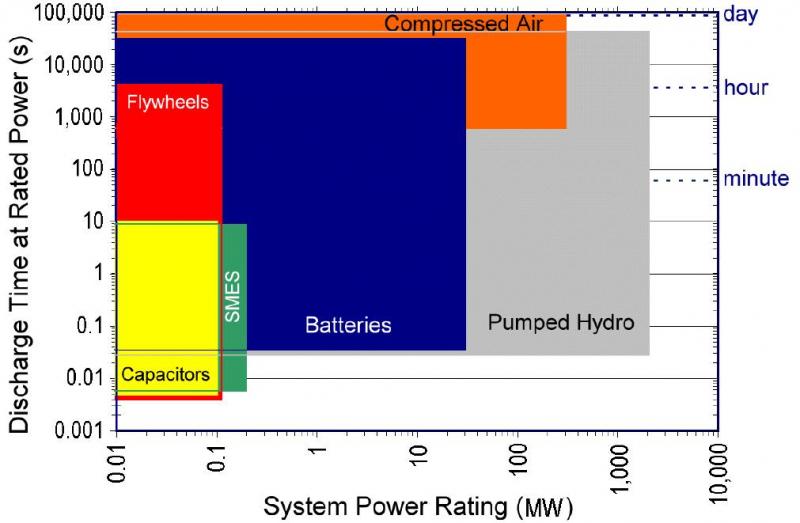

When used for frequency regulation applications, the cycle life of flywheels is not very certain, similiar to the uncertainty of Li-ion battery life cycles. This uncertainty is attributed to lack of available data for long term use of flywheel systems as this technology is relatively new in field operations. Compared to batteries, flywheels have five to ten times more power density, allowing them to store comparable amounts of power at much smaller volumes. Similiar to compressed air energy storage and pumped hydo, flywheel energy storage has a long lifespan and the capacity is similarly limited to the size of the flywheel system. However, in conrast to the aforementioned two storage technologies, flywheels can not supply comparable power for such long durations as those. Figure 1 below shows a comparison between flywheel technology and other forms of energy storage. Adding a larger number of flywheel system modules to the energy storage plant, as illustrated in Figure 1 below, is similar to adding more cells to a battery pack. Figure 2 shows how multiple flywheels can be arranged in a field unit, with the blue cyclinders housing the flywheels and buried mostly underground, charging and dicharging to a central control unit. Figure 3 shows an example of a self contained, above ground flywheel unit.

Figure 1: Energy Storage Comparison of Discharge Time and Power Rating

Figure 2: 1-MW/15-min Beacon Power flywheel in an ISO ancillary service application

Figure 3: Pentadyne GTX Flywheel

Pros:

- Flywheels have an exceptional response time on the order of 4 milliseconds or even less and can be sized for 100 kW to 1650 kW over durations up to an hour

- Exceptional Energy Density (100 Wh/kg – 1000 Wh/kg)

- Low maintenence

- High Efficiency (up to 95%)

- Long service life (potentially indfinite)

- Reduce the emissions a fossil fuel alternative would produce to provide comparable power corrections and regulation

Cons:

- Short discharge time (typically an hour or less)

- Requires complex magnetic bearings

- Requires very high quallity manufacturing for a balanced wheel

Article Author: Joshua N. R. Singh

Last Edited: 3/30/2015

Sources:

Pages 25, 96-98, 106-107, 115-120

https://depts.washington.edu/amtas/events/amtas_09spring/Fabien.pdf

http://www.climatetechwiki.org/sites/climatetechwiki.org/files/images/ex…